Why Distribution ERP Should Be Designed Around Exceptions, Not Happy Paths

It’s 2:47 PM on a Thursday. Your warehouse just discovered that 40% of an inbound container has water damage. Your biggest customer needs their order shipped today—but half the items are in that damaged shipment. Your purchasing manager is on vacation. The supplier is in a different time zone. And your current ERP system is showing everything as “on track” because the shipment technically arrived.

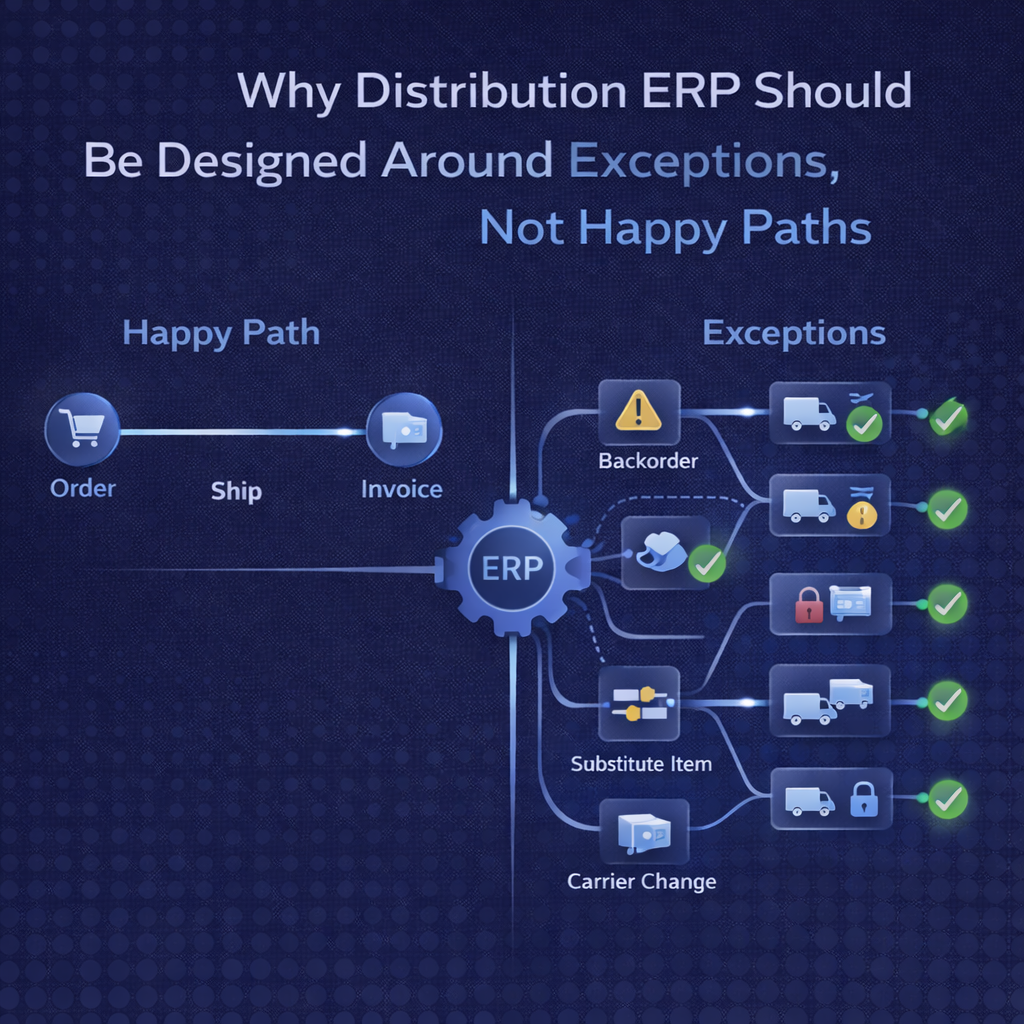

This is distribution reality. And if your ERP was designed around “happy path” scenarios—the theoretical world where orders arrive complete, inventory counts match perfectly, and customers never change their minds—you’re managing exceptions through spreadsheets, phone calls, and institutional knowledge rather than systematic processes.

The Happy Path Illusion in Distribution Software

Most ERP systems are architected around ideal transaction flows. Purchase orders arrive complete and on time. Sales orders ship as entered. Inventory accuracy stays near perfect. Pricing follows predetermined rules. These “happy paths” make for clean software demos and tidy process flowcharts.

But in actual distribution operations, the happy path is the exception.

Real distribution involves constant deviation from the ideal: partial shipments that require allocation decisions, quality holds that disrupt promised delivery dates, emergency orders that bypass standard workflows, pricing adjustments for relationship management, inventory discrepancies discovered during cycle counts, supplier substitutions that require customer approval, carrier issues that force mode changes mid-transit, and customer returns that need rapid disposition decisions.

Systems designed around happy paths treat these scenarios as edge cases requiring manual intervention. The software handles the 20% of transactions that go smoothly while forcing operators to work around the system for the 80% that involve complications. This creates a fundamental mismatch between how the software thinks and how distribution actually works.

Why Exceptions Are the Rule in Distribution

Distribution operations face a perfect storm of complexity factors that make exceptions inevitable. Unlike manufacturing, where you control production schedules, or retail, where standardized items flow to predictable locations, distribution sits at the intersection of supplier variability, customer urgency, and inventory constraints.

Supply chain unpredictability creates constant upstream exceptions. Suppliers ship partial quantities, substitute items without notice, deliver early or late, change packaging configurations, or have quality issues. Your ERP needs to handle these variations systematically rather than forcing warehouse staff to improvise workarounds.

Customer demand variability generates downstream exceptions. Orders arrive for out-of-stock items, customers change quantities after order entry, delivery dates shift based on project schedules, pricing requires approval for strategic accounts, and returns need rapid processing to maintain relationships. Each variation demands immediate system accommodation, not batch correction at end-of-day.

Physical inventory reality diverges from system records. Shrinkage occurs, damage happens during handling, cycle counts reveal discrepancies, bin locations change for efficiency, and lot tracking requires constant attention. Distribution can’t wait for month-end adjustments—inventory accuracy impacts immediate fulfillment decisions.

Multi-location complexity multiplies exception scenarios. Transfer orders face delays, inter-branch stock balancing requires rapid decisions, customer orders need multi-site fulfillment, and inventory visibility must account for goods in transit. Happy path systems assume single-location simplicity that doesn’t match multi-branch distribution reality.

The operational cost of exception handling in happy-path systems is substantial. Warehouse supervisors spend hours reconciling system discrepancies instead of optimizing operations. Customer service representatives manage delivery promises in spreadsheets because the ERP can’t track partial shipment status. Purchasing managers maintain shadow systems to track actual supplier performance rather than theoretical lead times. Finance teams create manual adjustments to reflect the reality that operational staff had to work around.

What Exception-Driven ERP Architecture Actually Means

Building distribution ERP around exceptions requires fundamental architectural decisions that differ from traditional happy-path design. It’s not about adding more features to handle edge cases—it’s about designing core transaction processing to expect and manage variation as the default state.

System intelligence at decision points means the ERP recognizes when transactions deviate from standard patterns and presents relevant options rather than blocking progress. When a purchase order arrives with quantities that don’t match, the system immediately surfaces allocation options based on sales order priority, customer importance, and inventory position across all locations. The operator makes an informed decision within the transaction flow rather than completing receipt then managing allocation in a separate process.

Workflow flexibility without customization enables operators to handle exceptions within standard processes. A partial shipment doesn’t require custom code—the system allows splitting order lines, updating delivery promises, and notifying customers as part of normal order management. Pricing exceptions don’t need special approvals workflow programming—authorization thresholds and notification logic are configurable within the platform.

Real-time constraint visibility gives operators complete context for exception decisions. When inventory allocation becomes necessary, the system shows not just current stock levels but incoming receipts, committed quantities, alternative items, and substitution history. Decision-makers see the full picture rather than toggling between screens to assemble fragmented information.

Automated exception detection identifies issues before they cascade into bigger problems. The system flags orders at risk due to inventory shortages, alerts purchasing when supplier delivery patterns deviate from history, and notifies customer service when commitments may be missed. Proactive management replaces reactive firefighting.

Transaction traceability maintains complete audit trails for every exception decision. When an order ships from multiple locations, or inventory adjustments resolve count discrepancies, or pricing overrides accommodate strategic customers, the system captures not just what happened but why. This documentation supports both operational learning and compliance requirements.

How Exception-Driven Design Changes Daily Operations

The operational difference between exception-driven and happy-path ERP becomes immediately visible in daily distribution workflows. Where traditional systems create friction, exception-aware platforms enable fluid decision-making.

Order promising transforms from best-guess commitments to data-driven accuracy. Rather than promising from theoretical inventory that may include damaged goods, allocated stock, or mis-located items, the system accounts for actual available-to-promise inventory across all locations, in-transit shipments, and realistic supplier delivery timeframes. Customer service representatives make commitments the warehouse can actually fulfill.

Inventory allocation moves from spreadsheet scrambling to systematic prioritization. When stock is insufficient to cover all demand, the system applies configurable business rules—customer tier, order profitability, delivery date urgency, contract obligations—to recommend allocation decisions. The purchasing manager reviews recommendations with full context rather than making isolated decisions based on partial information.

Supplier performance management shifts from periodic review to continuous adjustment. The system tracks actual lead times, fill rates, quality issues, and delivery reliability, automatically adjusting safety stock calculations and reorder points based on demonstrated performance rather than theoretical targets. Purchasing decisions reflect reality, not supplier promises.

Return processing accelerates from multi-day investigations to immediate disposition. When returns arrive, the system provides complete context—original order details, customer history, item profitability, quality patterns—enabling rapid decisions on replacement, credit, or restocking. Customer satisfaction improves while reducing tied-up inventory.

Cross-dock operations become manageable rather than chaotic. Inbound receipts immediately link to outbound orders, creating visibility into which items should bypass storage and go directly to shipping. The system manages the timing complexity and tracks exceptions when planned cross-dock items don’t arrive as expected.

Emergency orders flow through the system rather than around it. When a critical customer needs immediate shipment, the system accommodates priority processing while maintaining visibility and controls. Finance doesn’t discover off-system transactions during month-end close—everything flows through integrated workflows with appropriate approval tracking.

The time savings compound across the organization. Warehouse staff spend less time reconciling discrepancies and more time executing efficient fulfillment. Customer service representatives handle more orders because the system manages complexity rather than creating additional work. Purchasing managers focus on strategic supplier relationships rather than constant firefighting. Finance closes faster because operational reality matches system records.

The Technical Reality: Why Most ERPs Can’t Handle Exceptions Well

The inability of most distribution ERP systems to handle exceptions gracefully isn’t a feature gap—it’s an architectural limitation. Understanding why reveals what to look for in exception-capable platforms.

Legacy architecture constraints in older systems create fundamental brittleness. When core transaction processing was designed decades ago around batch processing and sequential workflows, adding exception handling requires bolting on custom code rather than native capabilities. Each exception type needs separate development, creating maintenance nightmares and inconsistent user experiences.

Module integration weaknesses force exception management outside the system. When inventory, purchasing, and order management are separate modules loosely connected through interfaces, handling exceptions that span processes becomes impossible within the platform. Partial shipments that trigger purchase orders for shortages and customer notifications can’t flow through disconnected systems—operators must coordinate manually.

Data model inflexibility prevents exception tracking. Systems built around rigid transaction structures can’t easily capture why an operator made a specific decision, what alternatives were considered, or what business rules applied. The audit trail shows what changed but not the context that drove the decision.

User interface limitations make exception handling cumbersome. When screens were designed for sequential data entry of happy-path transactions, adding functionality to handle variations creates cluttered interfaces and nested dialog boxes. Operators need multiple clicks and screen transitions to accomplish what should be single-action decisions.

Customization requirements for basic exception scenarios indicate architectural problems. If handling partial shipments, managing inventory shortages, or processing returns requires writing custom code or implementing workflow engines, the platform wasn’t designed for distribution reality. The cost and complexity of maintaining these customizations eventually exceeds the value of the ERP itself.

Cloud-native platforms solve these problems through fundamentally different architecture. Real-time data access eliminates batch processing delays. Unified databases prevent module integration issues. Flexible data models accommodate exception tracking. Modern interfaces enable contextual decision-making. And configurable business rules replace custom code.

The operational test is straightforward: can standard system functionality handle your three most common exception scenarios without customization? If the vendor demo requires mentioning “that would need custom development” or “we can build a workflow for that,” the platform isn’t exception-ready.

Exception Management in Specific Distribution Scenarios

Different types of distributors face characteristic exception patterns that reveal whether an ERP truly supports exception-driven operations or just claims to handle “special cases.”

Food and beverage distributors deal with constant lot tracking complexity. When a quality hold affects specific lot codes, the system must immediately identify all locations of that inventory, flag affected orders, suggest substitutions from acceptable lots, and track the disposition of held goods. Happy-path systems require manual intervention for each step. Exception-aware platforms automate the entire cascade.

Building materials distributors manage project-based delivery complexity. Orders for construction sites have hard deadlines, but supplier delays, weather disruptions, and project changes create constant schedule adjustments. The ERP needs to manage delivery date cascades, coordinate multi-supplier orders to arrive together, and handle partial shipments without losing project context.

Electronics distributors face rapid obsolescence and substitution management. When manufacturers discontinue items or introduce replacements, the system must manage customer notifications, inventory liquidation, and order substitution across thousands of SKUs. Trying to handle this in spreadsheets while the ERP continues processing orders against obsolete items creates chaos.

Chemical distributors require sophisticated compliance and safety management. Hazmat regulations, shipping restrictions, and customer certifications create exception scenarios with every order. The platform must enforce compliance rules while maintaining operational efficiency—blocking invalid shipments without creating friction for compliant orders.

HVAC distributors manage seasonal demand swings and emergency service needs. The mix of routine orders and critical emergency requests requires dynamic priority management. When a service technician needs a part immediately, the system must handle expedited processing, inventory allocation away from standard orders, and appropriate billing—all without breaking established workflows.

The pattern across verticals is consistent: distribution reality involves constant variation from ideal transactions. ERP platforms designed around exceptions handle these scenarios within normal workflows. Happy-path systems force operators to work around the software, creating data integrity issues and operational inefficiency.

Building an Exception-Capable ERP Strategy

Evaluating whether a distribution ERP can truly handle exception-driven operations requires looking beyond demo scripts at architectural capabilities and operational flexibility.

Requirements definition should start with your exception scenarios rather than happy paths. Document the twenty most common operational variations your team handles: partial shipments, inventory shortages, quality holds, emergency orders, pricing exceptions, return processing, supplier substitutions, and delivery date changes. Then require vendors to demonstrate standard functionality for each scenario—not customization promises, but out-of-box capabilities.

System demonstrations should focus on exception handling rather than routine transactions. Anyone can demo entering a perfect purchase order. Ask vendors to show partial receipts with allocation decisions, orders requiring multi-location fulfillment, inventory adjustments with reason codes and approvals, pricing exceptions with authorization workflows, and return processing with disposition logic. The quality of exception handling reveals the platform’s real capabilities.

Reference conversations should specifically address operational workarounds. Ask current customers how they handle partial shipments, manage inventory discrepancies, process emergency orders, and deal with supplier issues. If the answer involves spreadsheets, manual processes, or “we’re waiting for an enhancement,” the system isn’t exception-ready regardless of marketing claims.

Implementation approach must prioritize exception handling from day one rather than treating it as phase two functionality. The most critical workflows to validate before go-live are exception scenarios, not happy paths. Testing must include realistic operational variations: damaged inventory, shortage situations, urgent customer needs, and supplier problems. If these don’t work smoothly, the system will fail under real-world conditions.

Change management should emphasize the operational empowerment that exception-capable systems enable. Rather than training staff to work around system limitations, focus on how the new platform allows making better decisions with complete information. The transition from reactive firefighting to proactive exception management represents a fundamental shift in operational culture.

Continuous improvement becomes possible when the system captures exception patterns rather than forcing offline workarounds. Regular review of exception frequency, decision patterns, and resolution timeframes reveals operational improvement opportunities. This visibility is only possible when exceptions flow through the system rather than around it.

The ROI of Exception-Driven ERP Design

The financial impact of moving from happy-path to exception-aware ERP architecture manifests across multiple operational dimensions. While traditional systems force managing exceptions outside the platform, exception-capable ERP delivers measurable benefits.

Operational efficiency gains come from handling variations within workflows rather than around them. Companies typically report 30-40% reduction in time spent on exception management when moving from traditional to exception-aware platforms. Warehouse supervisors spending three hours daily on allocation decisions and discrepancy resolution reduce this to under an hour. Customer service representatives handling 25% more orders because the system manages complexity rather than creating additional work.

Inventory optimization improves when the system accounts for actual constraints rather than theoretical availability. Safety stock calculations based on real supplier performance rather than promised lead times typically reduce excess inventory by 15-20% while improving fill rates. More accurate available-to-promise logic reduces emergency freight expenses by eliminating over-commitments based on mis-allocated inventory.

Customer satisfaction increases measurably when promises match reality. Delivery date accuracy improving from 75% to 95% because the system accounts for actual inventory availability, supplier reliability, and operational constraints directly impacts customer retention. Return processing accelerating from three days to same-day improves satisfaction while reducing tied-up inventory value.

Staff productivity jumps when employees work with the system rather than around it. New employee training time typically decreases by 40-50% because standard workflows handle variation—no tribal knowledge of workarounds required. Institutional knowledge loss when experienced staff leave has less impact because the system codifies exception management rather than relying on individual expertise.

Financial close efficiency improves dramatically when operational reality matches system records. Month-end close processes that took 5-7 days with constant reconciliation and manual adjustments complete in 2-3 days when exceptions flow through the system with appropriate tracking and approval. Finance team capacity freed from reconciliation work can focus on analysis and strategic planning.

Compliance and auditability strengthen when exception handling is systematic rather than ad-hoc. Complete audit trails for pricing overrides, inventory adjustments, and allocation decisions provide documentation for internal controls and regulatory requirements. Risk exposure from undocumented manual processes affecting financial results decreases substantially.

For a mid-sized distributor with $100 million in annual revenue, the financial impact typically includes $200K-300K in annual labor cost savings from efficiency gains, $400K-600K in working capital improvements from better inventory management, $150K-250K in reduced emergency freight expenses from fewer over-commitments, and immeasurable value from improved customer retention through better service reliability. The ROI timeline for moving to exception-capable ERP typically runs 12-18 months even before counting strategic benefits.

What Exception-Driven Design Means for Implementation

The architectural differences between happy-path and exception-aware ERP platforms fundamentally change implementation approaches and success factors.

Configuration over customization becomes the standard approach. Rather than writing custom code to handle operational variations, implementation teams configure business rules, approval workflows, and decision criteria within the platform. This distinction is critical: configured exception handling remains supportable across software updates, while custom code creates technical debt and upgrade complications.

Realistic testing scenarios must include operational complexity from the start. Happy-path testing—perfect orders flowing smoothly through the system—validates nothing about real-world readiness. Implementation success requires testing partial shipments, inventory shortages, quality holds, emergency orders, and supplier issues before go-live. If these scenarios don’t work smoothly in testing, they’ll fail catastrophically in production.

Process standardization becomes achievable when the system accommodates operational reality. Legacy ERP implementations often fail because standardization requires eliminating sensible exception handling that the system can’t support. Exception-capable platforms allow standardizing how exceptions are managed rather than pretending they don’t exist. The result is consistency without brittleness.

Training effectiveness improves when workflows match operational reality. Rather than teaching staff “here’s the happy path, but when X happens you need to work around the system,” training covers how to handle variations within normal processes. New employees become productive faster because the system guides them through exception scenarios rather than requiring institutional knowledge.

Go-live confidence comes from knowing the system handles complications rather than just routine transactions. The most stressful period of any ERP implementation is when operational reality hits the new system. If the platform manages exceptions systematically, that stress remains manageable. If operators must immediately devise workarounds, the implementation risks failure regardless of how well happy paths were tested.

Post-implementation optimization focuses on continuous improvement rather than emergency fixes. When exceptions flow through the system with complete tracking, regular review reveals patterns and opportunities: which suppliers consistently create problems, which customers require frequent exceptions, which inventory items drive allocation decisions. This visibility enables strategic improvements rather than reactive firefighting.

The implementation timeline for exception-capable platforms often runs shorter than happy-path systems despite greater apparent complexity. The reason is counterintuitive but consistent: when the platform handles operational reality out of box, implementation focuses on configuration rather than customization. The absence of custom development cycle-time dramatically accelerates deployment.

Moving Forward: From Happy Path Illusions to Operational Reality

The distribution industry has accepted for too long that ERP systems handle ideal transactions while operators manage actual complexity through workarounds. This acceptance isn’t wisdom—it’s resignation to inadequate software architecture.

The operational cost compounds daily. Warehouse supervisors reconciling discrepancies instead of optimizing workflows. Customer service representatives managing spreadsheets because system visibility is inadequate. Purchasing managers maintaining shadow systems to track supplier reality. Finance teams creating manual adjustments to align system records with operational truth. The productivity lost across these activities typically represents 10-15% of operational staff time—a hidden tax that traditional ERP imposes on distribution businesses.

The strategic cost runs deeper. When exception management happens outside the system, the organization loses visibility into operational patterns. Which suppliers consistently create problems? Which customers require frequent special handling? Which inventory items drive allocation complexity? These questions can only be answered when exceptions flow through the system rather than around it. Without this visibility, continuous improvement becomes impossible—you’re managing the symptoms rather than addressing root causes.

The competitive risk intensifies as customer expectations for service reliability and transparency increase. Distributors competing on “we ship what we promise when we promise it” can’t deliver on that commitment when their ERP treats accurate promising as an edge case. Companies claiming omnichannel capability can’t execute when their system can’t handle multi-location fulfillment complexity. The gap between market positioning and operational capability exposes businesses to competitive disadvantage.

Modern cloud-native ERP platforms designed specifically for distribution eliminate these compromises. Real-time visibility replaces batch processing delays. Unified architecture prevents module integration issues. Configurable business rules replace custom code. Contextual interfaces enable informed decision-making. And exception management becomes a systematic capability rather than operator heroics.

The question for distribution executives isn’t whether to prioritize exception handling—operational reality makes this mandatory. The question is whether to continue managing exceptions around inadequate systems or implement platforms designed for distribution’s actual complexity. The operational, financial, and strategic benefits of exception-capable ERP make the answer clear.

For distributors ready to move beyond happy path illusions and implement ERP designed around operational reality, Bizowie provides the exception-capable platform that modern distribution demands. Our cloud-native architecture, distribution-specific functionality, and real-time integration enable systematic exception management within normal workflows—no customization required.

Schedule a demo to see how exception-driven ERP design handles your specific operational scenarios, or explore how Bizowie eliminates the compromises that traditional systems force on distribution businesses.